Concrete gravity retaining walls have become a popular choice for residential and commercial landscaping projects across New Zealand in recent years. These solid concrete walls are engineered and designed to resist the lateral pressure of soil using their sheer weight and mass.

With heights ranging from just a few feet up to 6 meters or more, concrete retaining walls are ideal for areas that require terracing or tiered levels, or where existing slopes need to be stabilized. They allow landscape architects and homeowners to create usable flat yard spaces on properties with dramatic elevation changes or steep embankments.

Unlike other retaining wall options which rely on mechanical stabilizing components, the gravity wall uses no reinforcements or anchoring. This simplicity along with their natural aesthetic appeal makes concrete retaining walls a go-to solution for a wide variety of landscaping needs in New Zealand.

This is a type of retaining wall system that uses the weight of the concrete and frictional forces to hold back soil, rocks, and other materials. They are called "gravity" walls because they rely on gravity and their mass to provide the resistance needed for stability.

Unlike other retaining wall systems that use reinforcements like geogrids or tiebacks, concrete gravity walls use their sheer bulk and heft to retain the pressure from the material behind them. They have a solid concrete slab construction without any built-in reinforcements. The concrete slab is thicker at the bottom and tapers towards the top. This design allows the thickest, heaviest part of the wall to be at the bottom for maximum stability.

They can be built straight or curved into landscape designs. They are commonly used for residential landscaping projects like building garden beds, terraces, and planters. But they also work for larger commercial projects like supporting highways, bridges, and embankments. Their simple and rugged design makes them a versatile and durable retaining wall option.

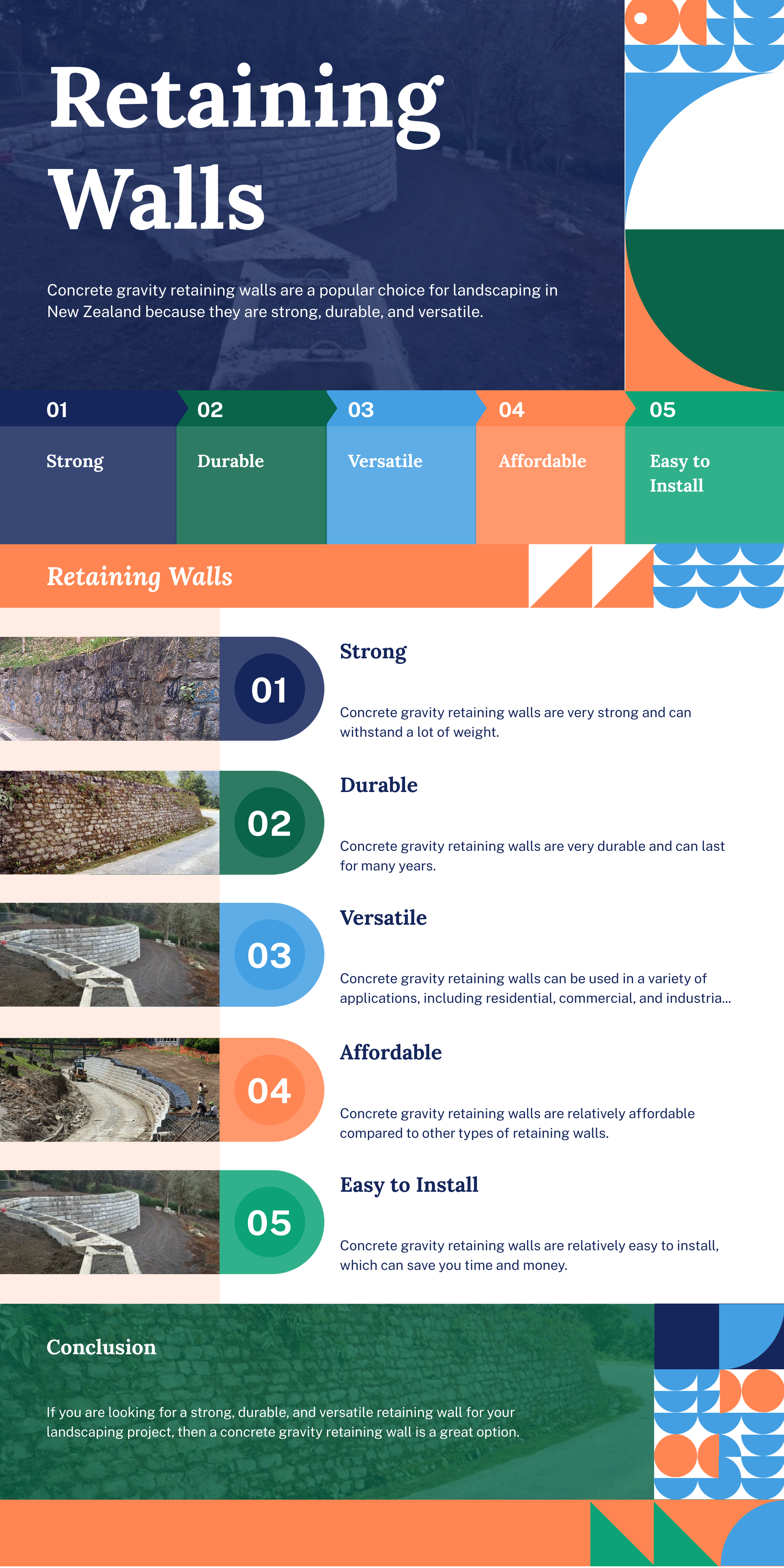

Concrete gravity retaining walls offer several advantages that make them a popular choice for residential and commercial projects in New Zealand.

Concrete is an incredibly strong and durable material capable of withstanding the elements and natural ground pressures for decades. Unlike other retaining wall materials like wood, concrete does not rot or degrade over time. Properly constructed concrete walls have an expected service life of 50-100 years. This durability means fewer repairs or replacements down the road.

Though concrete on its own is not the cheapest material, concrete retaining walls are cost-effective in the long run compared to other wall types. Wood retaining walls often need replacement every 10-15 years. Concrete walls have a much longer lifespan, avoiding frequent replacement costs. Concrete also does not require specialized labor or equipment for installation like other materials. This helps reduce overall project expenses.

Concrete gravity walls utilize the weight and mass of concrete to hold back soil through gravity. This means they do not require complex engineering or geogrid soil reinforcement like many other retaining wall styles. The simple installation process using poured concrete makes it a great choice for DIY homeowners. Professional landscape contractors also appreciate the straightforward construction of concrete retaining walls compared to block or stacked stone designs.

Concrete gravity retaining walls are designed to resist the lateral pressure of the soil behind them through their sheer weight and mass. Unlike other retaining wall systems that use reinforcements like geogrids or anchors, the gravity wall relies on the dead weight of the concrete itself to provide stability against overturning and sliding forces.

The key principle is that the self-weight of the wall counteracts the soil's lateral earth pressure. A larger wall requires a wider base and footing to provide enough resisting moment. The designer determines the appropriate dimensions, usually tapering the wall thicker at the bottom and thinner at the top. This allows gravity to stabilize the wall against the increasing soil pressure higher up.

The height of a gravity retaining wall is limited by how much weight is needed to resist the active pressure. Excessive height requires a prohibitively wide base, making the footprint impractical. Standard gravity walls are typically in the range of 4 to 7 meters tall. For heights beyond 7 meters, reinforced walls or tiered gravity walls stacked on top of each other are more optimal solutions. The tiered configuration breaks up the total height into smaller stabilized sections.

When engineered and constructed properly, the sheer mass of a concrete gravity wall can safely retain substantial soil with minimal reinforcement. This simplicity and inherent durability are why they continue to be a popular earth retention method.

Concrete retaining walls utilize a few key materials to achieve maximum strength and durability. The concrete itself is a critical component. Typically, a mix of Portland cement, aggregates like gravel or crushed stone, water, and other admixtures are combined to create the concrete. The specific proportions of the concrete mix can be tailored to achieve the desired strength and workability needed for retaining wall construction. Using a concrete mix with a high compressive strength is recommended. This allows the retaining wall to withstand the lateral earth pressures acting against it over time.

The other essential material is steel rebar reinforcement. Steel rebar rods are placed within the concrete retaining wall during the construction process. The rebar provides tensile strength to resist flexural bending or cracking. The size and spacing of the rebar is determined by an engineer, based on the loads and height of the retaining wall. Proper rebar placement and concrete consolidation around it is key to achieving a durable, resilient gravity retaining wall. The combination of high-quality concrete and steel reinforcement gives concrete retaining walls their renowned strength and longevity.

The construction of concrete gravity retaining walls involves several key steps:

The first step is excavating the site to the designed width and depth. Excavators and backhoes are typically used for this initial digging and earth removal. The excavation is dug slightly wider than the base of the wall to allow for formwork. Proper drainage and retention of the remaining soil is critical during the excavation process.

Formwork made of wood, steel or aluminum is constructed on the excavated foundation to provide the mold for pouring the concrete. The formwork includes inserts for steel rebar that will reinforce the concrete. The rebar grid is wired together and placed inside the formwork before concrete pouring.

The concrete is poured into the formwork and rebar grid to construct the gravity wall structure. Concreting is done in sections or lifts of approximately 0.6-0.9 meters at a time. Once it has been set, the forms are removed, and the procedure is repeated to attach the following section above. Adjoining sections have steel dowel bars extending out over them to unite the sections. The front can be textured or colored as implored. Backfill soil is situated behind the wall once sections have fully hardened.

Proper curing time is allowed between lifts to gain concrete strength. The result is a reinforced concrete retaining wall able to resist soil pressures through its weight and dimensions.

Proper maintenance is crucial for concrete gravity retaining walls to maximize their lifespan. Here are some key maintenance tips:

It's critical to maintain proper drainage behind the wall to prevent buildup of hydrostatic pressure. Make sure drain pipes are functional and free of debris. Clear out any soil, vegetation or other material that may clog weepholes. This allows water to properly drain through the wall and relieve pressure.

Periodically inspect the wall for any new cracks or bulges which may indicate wall failure. Small hairline cracks are generally not a major concern. However, larger cracks or bulges can compromise the structural integrity. Consult an engineer to evaluate any questionable cracks or bulges. They can advise on potential repairs or reinforcement to stabilize the wall if needed.

Overgrown vegetation behind the wall can cause soil erosion and retain moisture, leading to additional pressure. Trim back any excessive vegetation growth.

Check for signs of erosion or soil washout near the base of the wall. Refill eroded areas with compacted granular fill to prevent undermining the foundation.

Any exposed rebar should be cleaned and re-coated with a concrete patching compound to prevent corrosion.

Concrete gravity retaining walls require proper design and construction to ensure safety and prevent collapse. Some key factors to consider for safety include:

Regular inspection and maintenance of drainage, backfill, and concrete are necessary to prevent deterioration over time. With good design, materials, and construction practice, concrete retaining walls can safely withstand lateral soil pressures for decades. Proper safety precautions protect workers during the wall construction process as well.

While concrete is the most common material used for retaining walls in New Zealand, there are some alternatives worth considering:

Timber retaining walls use stacked railway sleepers or landscape timber to hold back soil. They have an attractive, natural look and can be less expensive than concrete. However, timber walls don't last as long as concrete and can rot over time. They require more maintenance by replacing rotten timbers. Timber walls should not be used for high, load-bearing walls.

Interlocking concrete blocks are another option, assembled like bricks or Lego. They can create attractive patterns and curves. Block walls are easier for DIY construction than poured concrete. However, they have a higher risk of failure if not properly engineered and installed. Blocks are more expensive than poured concrete per square foot.

Galvanized steel sheets can be used to create retaining walls, sometimes with a face of stone or concrete blocks. Metal retaining walls need professional engineering and installation but can support very heavy loads. Metal walls can potentially corrode over time if the galvanized coating is compromised.

Gabion walls use stacked wire baskets or cages filled with rock. They create a natural, rustic appearance suitable for some landscapes. However, they are generally more expensive than concrete and require crushed rock fill. Gabions need to be properly engineered and constructed to avoid bulging or collapsing. The wire cages may eventually corrode.

For most retaining wall needs in New Zealand, properly engineered and installed concrete gravity walls are generally the most cost-effective, durable, and low maintenance solution. The alternatives each have their pros and cons to consider. Consulting a professional landscape architect is recommended to determine the best option.

When considering a concrete gravity retaining wall for your property, the importance of professional expertise cannot be overstated. These structures are not only foundational to your landscape's integrity but also to the safety and longevity of your investment. Here's why you should trust the specialists at LandscapingHQ for your retaining wall needs:

With LandscapingHQ, you invest in enduring strength and an aesthetically pleasing landscape. Experience the difference of working with our professional retaining wall specialists and see why we are New Zealand's trusted choice for retaining walls.

Concrete gravity retaining walls have become the go-to solution for landscaping in New Zealand for good reason. The key benefits that make concrete gravity walls ideal include their inherent strength and weight supporting retained soil through friction and mass. They require minimal maintenance, resist weathering, and have a long service life. With thoughtful engineering and construction using reinforced concrete, these massive walls can be built tall and hold back substantial amounts of earth.

Though more expensive initially than other retaining methods, concrete gravity walls offer a solid return on investment over time. They are customizable in aesthetic design yet extremely stable structurally. For homeowners, developers, and infrastructure projects across New Zealand, concrete retaining walls tick all the boxes as a tried-and-true landscaping workhorse.

When engineered and constructed properly, concrete gravity retaining walls stand the test of time. They have proven themselves over decades as the go-to retaining solution for New Zealand's landscape needs. If you have a retaining wall project upcoming, consider utilizing these ubiquitous staples of Kiwi landscaping.

The wall retains soil in a vertical or near-vertical position, which is crucial for creating leveled areas in landscaping, preventing landslides, and supporting construction on slopes.

It works by providing a significant weight to resist the lateral forces from the soil it's retaining. The wall's design and mass counter these forces to maintain stability.

Key considerations include soil characteristics, wall height, load types, compliance with local building codes, and environmental factors. Proper calculations ensure the wall is adequately designed for durability and stability.

Main components typically include a base slab, a vertical wall which may slightly incline towards the retained material, and extensions like a toe or heel for extra stability. Steel reinforcement is often added to enhance strength.

Concrete gravity retaining walls are primarily made from concrete with steel rebar reinforcement. They may also include drainage systems to manage any water pressure building up behind the wall.